AUDIT

An audit enables us to understand how a company operates, and this is what will enable NEYRTEC MINERAL to identify the strengths and weaknesses of the existing site or coming one. This audit is carried out by our team along the following lines:

- On-site visit

- Analysis of existing situation

- Performance measurement

- Optimization and improvement proposals

Audits are particularly relevant in the mining sector, where technical and operational failures can lead to high costs and environmental consequences. An audit not only ensures compliance with regulations, but also optimizes the performance and efficiency of existing installations.

Process and mechanical engineering: our core business for wet processing engineering.

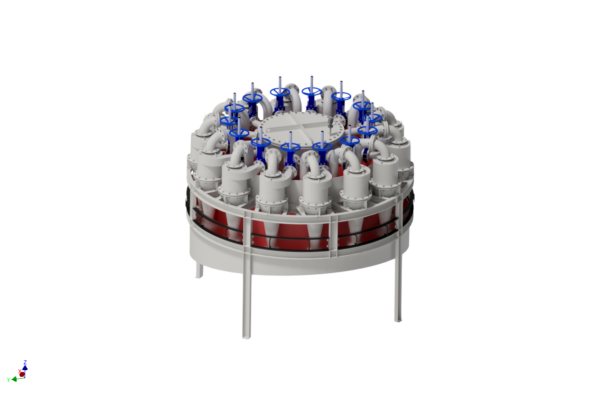

NEYRTEC MINERAL solutions include process and mechanical engineering, aimed at designing and implementing optimized processes to meet the specific needs of each customer. This includes:

- process definition and equipment sizing

- Laboratory and pilot tests

- calculations and development

- site survey

- project engineering and action plan monitoring

Process and mechanical engineering also includes preventive maintenance of equipment, ensuring maximum longevity and minimizing the risk of breakdowns or complications in machine operation.

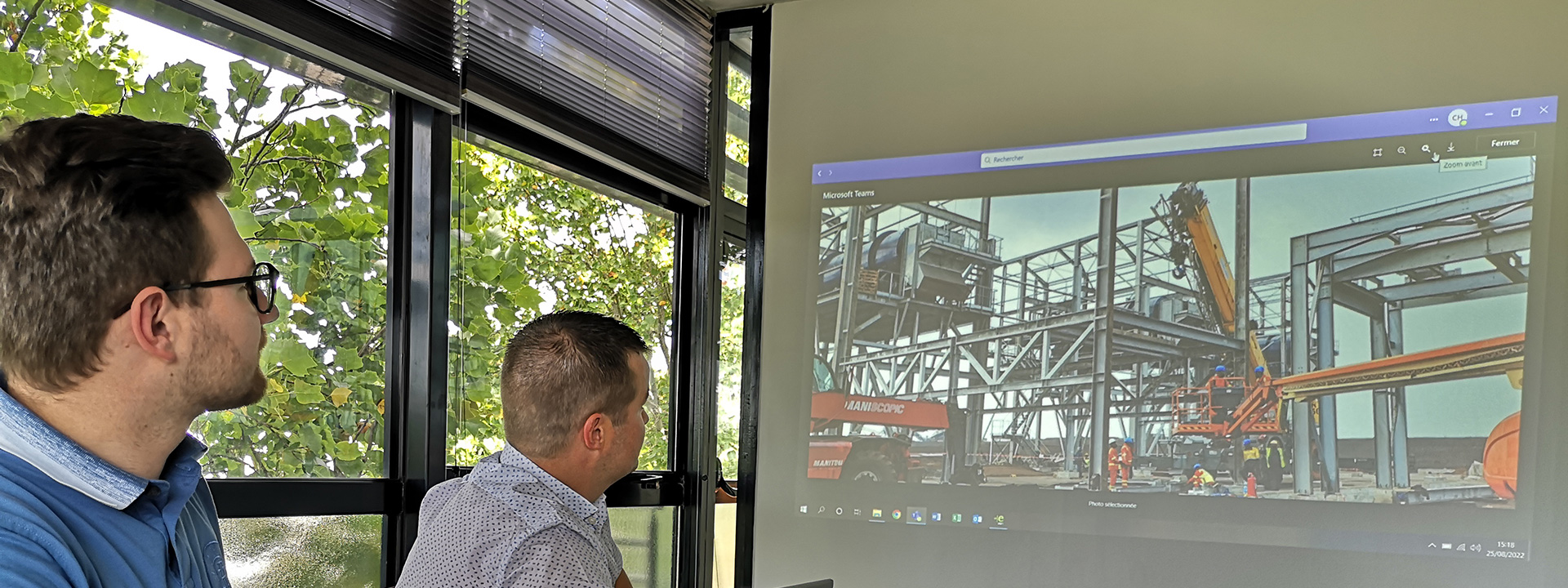

On-site manufacturing and integration: a turnkey service for optimal installation

NEYRTEC MINERAL solutions also include on-site manufacturing and integration services, providing real support throughout the project. Our teams provide customized design, manufacture and installation of equipment specific to your needs, guaranteeing optimum performance and maximum efficiency. Services include:

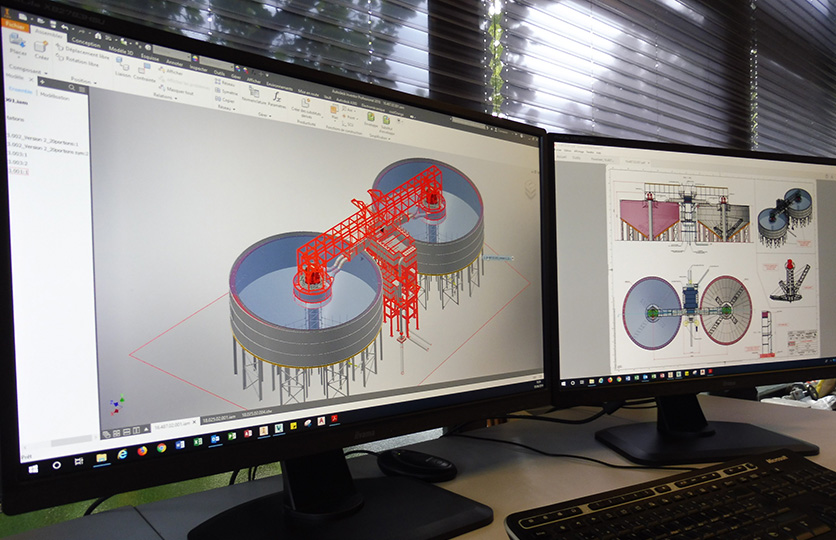

- 3D plant design

- Planning and managing production according to technical specifications

- Production monitoring and control

- Delivery

- On-site installation and integration by experienced professionals.

- Commissioning

NEYRTEC MINERAL guarantees compliance with current local and international regulations, while ensuring the quality of the materials used, adherence to deadlines and optimal integration of equipment into existing facilities.

Pilot tests: a crucial stage in validating the performances of new solutions

A key stage in your project involves our NEYRTEC MINERAL pilot plant and test laboratory in Lorient, France. Before large-scale deployment, it is essential to carry out pilot tests to ensure their effectiveness and reliability. This demonstrates the feasibility of your project and defines process performance guarantees. Our process team relies on full-scale tests.

The pilot includes some of the key equipment for materials valorization:

- a scrubber (0.5 m/1.5m) for materials removal.

- a hydrocyclone test bench with 5 to 20 µm cuts for hydraulic classification, and an hydroclassifier Lavodune.

- 2 attrition cells for surface preparation

- a dewatering screen for particle size classification, dewatering and screening

- a spiral bench for gravimetric separation with a flow rate of 4T/h (10m3/h).

Discover NEYRTEC MINERAL equipment

WITH YOU TO SUCCEED

Whether you’re in France or abroad, our NEYRTEC MINERAL team is ready to listen, discuss and support you in the realization of your projects. Our expertise and experience guarantee you with a tailored answer.