OUR BENEFITS

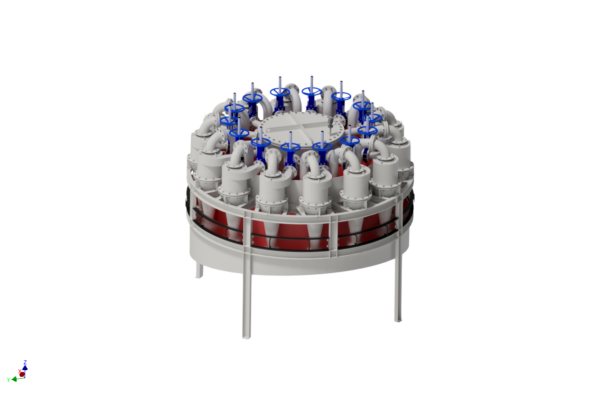

NEYRTEC MINERAL conditioners have been designed to optimize the flotation phase of mineral materials.

Before entering the flotation cells and proceeding to the separation phase, the pulp must be conditioned with flotation reagents (depressant, foaming agent, activator, collector, pH regulator).

This action is done in cylindrical tanks agitated by a propeller, known as conditioners.

- OPTIMIZED DESIGN

- LOWER ENERGY CONSUMPTION

- HOMOGENEITY GUARANTEED

ENGINEERING

NEYRTEC MINERAL has a pilot on which tests are carried out to define performance targets.

Read more

FEATURES

NEYRTEC MINERAL conditioners are designed to ensure efficient mixing of the pulp and reagents in the flotation phase.

Pulp and reagents are fed directly into the inner recirculation tube, where they are mixed.

This controlled recirculation eliminates the isssue short-circuiting the pulp and improves its flow inside the tank. If pulp tends to foam, it passes through the tube, recirculates and is broken up by the action of the propeller.

The overflow outlet offers 3 possibilities of adjustment.

- Tests in our in-house laboratory to define performance objectives.

- Wide range up to 6m diameter.

- Higher recovery rate.

EXAMPLES OF INSTALLATIONS

WE GUARANTEE YOUR SATISFACTION

Our team of technicians is at your disposal to intervene on your sites. Whether you need technical spare parts, an emergency intervention or a situation assessment, don’t hesitate to contact us!

ADDITIONAL EQUIPMENT

WITH YOU TO SUCCEED

Whether you’re in France or abroad, our NEYRTEC MINERAL team is ready to listen, discuss and support you in the realization of your projects. Our expertise and experience guarantee you with a tailored answer.