NEYRTEC MINERAL puts all its expertise in waste reprocessing and recovery, and more broadly in recycling markets, at your service. We can help you clean up disused industrial sites, treat effluents laden with mineral particles or carry out soil decontamination projects. Our services can include piloting tests to validate new processes. We can also reprocess past process water and compact residual sludge.

Associated processes for recycling materials

NEYRTEC MINERAL has a wide range of equipment and processes for all waste treatment and recovery projects. A closer look at the processes involved.

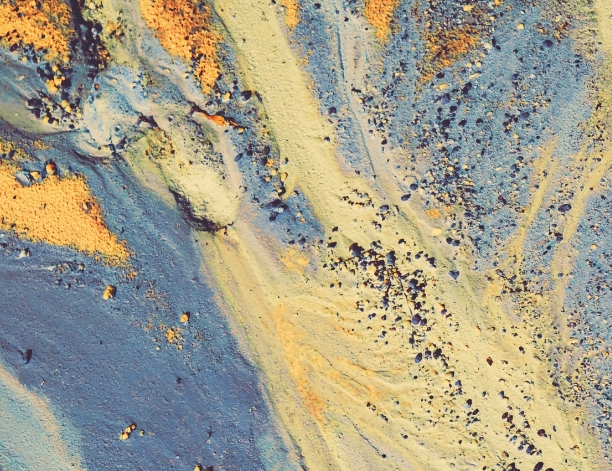

>> Cleaning polluted soil

This process is used on all soil decontamination sites. The aim is to restore the soil to its natural function.

>> Sand removal

The aim of this process is to wash the sand free of pollutant particles. It can sometimes be combined with the dewatering or separation process.

>> Effluent treatment

By recovering wash water for later reuse, the effluent treatment process contributes to preserving the environment.

>> The three types of separation for recycling

NEYRTEC MINERAL offers a range of equipment for chemical, gravimetric and granulometric separation.

>> Fluid agitation

All material reprocessing processes require mixing and stirring equipment. The final objective is the separation phase.

>> Crushing materials

The grinding process produces sand or aggregates. Their size is suitable for other reprocessing applications.

Materials

Thanks to its recognized know-how and 150 years of expertise, NEYRTEC MINERAL is able to add value to a wide range of materials. We add value by reprocessing and recycling this waste. These include construction waste, iron ore, phosphates, copper, bauxite, kaolin and sand.

Case studies

WITH YOU TO SUCCEED

Contact us if you have any technical questions about our equipment for materials recovery and recycling.