OUR BENEFITS

NEYRTEC MINERAL dewatering screens are used to perform a dewatering operation that considerably reduces the moisture content of materials. This step facilitates the handling and

the storage in heap of materials while optimizing recycling of cleaning water. The vibration created by the 2 out-of-balance motors improves water flow between the materials/grains to be treated. For specific materials, NEYRTEC MINERAL has a pilot unit to define performance guarantees.

- NEW DESIGN

- FRAMES PROTECTION

- BETTER PERFORMANCE

ENGINEERING

NEYRTEC MINERAL has a pilot on which tests are carried out to define performance targets.

Read more

FEATURES

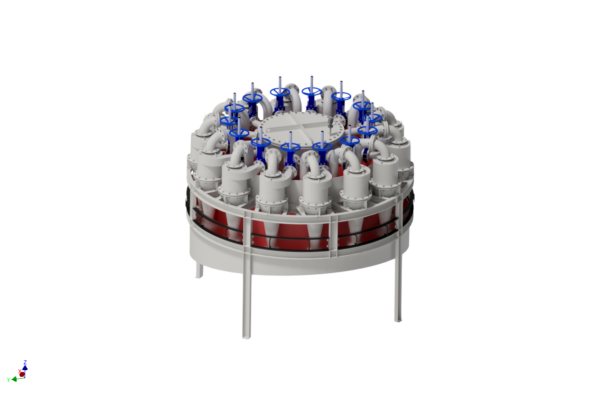

NEYRTEC MINERAL vibrating dewatering screens are mainly composed of two sides, a beam with 2 motorized vibrators and a filtering surface composed of a support frame on which the grids (craked) are fitted. The vibration module generates a linear and unidirectional movement ensuring the advancement of the product towards the output threshold. The vibration module creates an accelerating force that improves the flow of water between the grains to be treated.

Stainless steel or polyurethane cracking grids are mounted horizontally in the bottom of the unit and vertically in the back wall. NEYRTEC MINERAL defines grate gap widths according to the materials to be dewatered and the performance to be achieved. In addition, the shaft of each motorized vibrator is fitted with adjustable centrifugal weights, enabling the vibration amplitude to be varied to suit the flow rate to be treated.

- Range from 0.36 m² to 10 m².

- Adjustable vibration amplitude to meet the flow rate to be treated.

- Residual moisture around 15% depending on materials.

EXAMPLES OF INSTALLATIONS

WE GUARANTEE YOUR SATISFACTION

Our team of technicians is at your disposal to intervene on your sites. Whether you need technical spare parts, an emergency intervention or a situation assessment, don’t hesitate to contact us!

ADDITIONAL EQUIPMENT

CASE STUDIES

WITH YOU TO SUCCEED

Whether you’re in France or abroad, our NEYRTEC MINERAL team is ready to listen, discuss and support you in the realization of your projects. Our expertise and experience guarantee a tailored response.